Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Abstract: Rapid Prototype is also called Hand model ( first plate model) ,is an important expression of design. The emergence of modern manufacturing processes ( e. g. CNC machining,silicone mold flipping,rapid prototyping,Soft Tooling, etc. ) has resulted in shorter cycle time, higher precision,and versatility in the choice of materials. In this article,the silicone mold overturning technology,the rapid prototyping process for the production of prototypes and their application in automotive light manufacturing are discussed.

Key words: rapid prototype; CNC machining ; silicone mold; rapid prototyping

With the continuous improvement of computer aided design (CAD)/computer aided Design (CAM) technology, the new car development process of major automobile brand manufacturers is also quietly changing. From the original drawing → mold → validation → modify the mold, the data directly changed to the current data → fast sample → validation → modify the data. The change allowed car makers to develop new products several times faster and at a much lower cost. Therefore, almost all OEMS are using rapid prototyping equipment of different processes to make rapid samples, so as to meet the needs of different stages of design. Due to the change of the development process of OEMS, the internal new product development process of OEMS suppliers has been changed. Rapid prototyping is a crucial part of the new development process.

The quick sample making of the whole automobile lamp is based on different materials and different processing methods, which can efficiently and accurately produce the product model to meet the needs of engineers. The traditional rapid sample is mainly made by hand with clay, gypsum and other materials, but the processing cycle is long and the precision is low. The current mainstream of samples production technology, the computer numerical control (CNC) processing, rolling over the silicone mold, rapid prototyping, effectively combined with the simple steel production way, rather than simply using one or two kinds of processing methods for production, so again makes processing materials, optional sex is becoming more diverse, sample maker can even according to light the function of each component, select material production, so as to make the quick samples are more relevant original design concept, whether from the assembly to verify, or validation of the performance test, can get a certain amount of content. Thus, the practical application of the quick sample is further improved, and even "multi-purpose one piece" is achieved, making instructive contribution to the mass production of products of enterprises.

This article foucs on the application of silicone mold technology and rapid prototyping technology in the headlamp industry.

1. Demand for quick sample for headlight development

With the increasingly fierce competition in the social market and the continuous development and expansion of the automobile industry, the major automobile manufacturers have higher and higher requirements for the design ability of automobile lights manufacturing enterprises.(2) After the completion of the sample reliability is high, can participate in the experiment;(3) Due to the continuous improvement of the lamp shape and function, the assembly accuracy is also improved, so that the quick sample more fit the product design intention;The shortening of project management cycle,

So that the production cycle of the sample is constantly compressed.In order to efficiently complete the rapid sample, the traditional and single manual production process can no longer meet the requirements. Therefore, both the production accuracy, production equipment and production process of the rapid sample need to be constantly improved.High efficiency,

The characteristics of high precision enterprises in the first place, rapid prototyping technology and silicone mold technology have been further developed.

2. Rapid prototyping technology

2.1 Principle of rapid prototyping

The application of rapid prototyping technology in the automotive industry is also called RP sample. This technology is based on the integration and development of CAD /CAM technology, laser technology, computer numerical control technology, precision servo drive technology and new material technology. The applications of rapid prototyping technology in the market include 3DP(3D Printing), FDM(Fused Deposition Modeling), SLA lithography, SLS(Selected Laser Processing) Laser Sintering, DLP(Digital Light Processing) and lithography UV UV molding technology, the basic forming principle of "layered production, layer layer superposition". FIG. 1 shows the rapid prototyping equipment.

With the development of rapid prototyping technology, the processing technology has changed from the traditional "removal" processing (that is, the material which is larger than the workpiece is removed to the workpiece) to the new "addition" processing (that is, layer upon layer of blank gradually superposition into the workpiece) without the help of any processing tools.

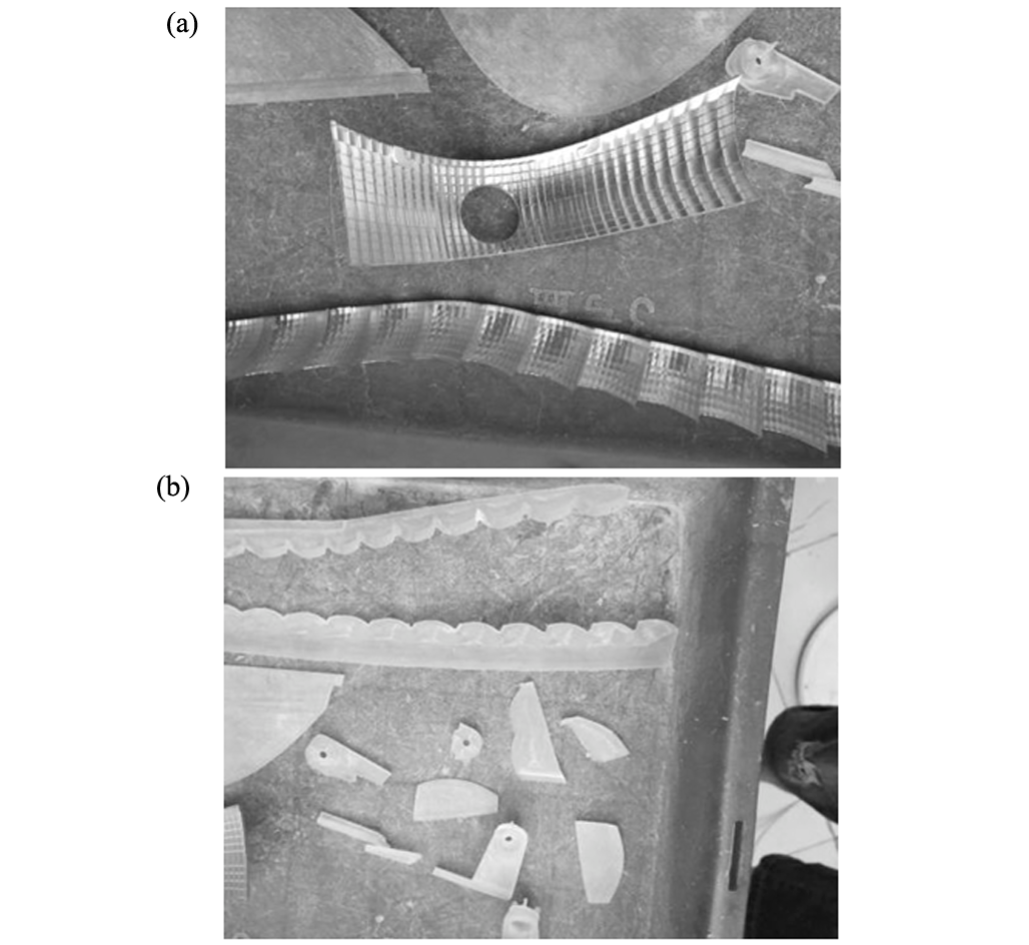

Mold and fixture, directly receive product CAD data, quickly manufacture the sample, mold or model, only need the traditional processing method of 30% ~ 50% of labor hours and 20% ~ 35% of the cost. In addition, compared with the simple CNC processing method, some complex structures need to be disassembled, so there is no method to ensure the integrity of the product. Figure 2 shows that CNC processing method is used to divide the reflector into reflection area and side wall processing.

Fig.1 3D printers

Fig.2 Spliting the reflector for processing

( a) Reflection area;

( b) Side wall

Simple CNC machining of some complex parts cannot be processed as a whole, only disassembly. And it is necessary to make some new positioning structures when disassembling parts,As far as possible to ensure the position of accuracy of audit splicing. However, when using rapid prototyping technology, it is no longer difficult to process Complex Part Structures,As shown in Figure 3.

Fig. 3 Rapid prototyping car lighting ring

It can be said that rapid prototyping technology is the combination of CAD, CAM and computer Digital control (CNC) combines rapid prototyping with direct digital manufacturing. And through the precision servo drive technology, the precision of the molded product is controlled to about 0.1 mm.

2. 2 Application of rapid prototyping on car lights

With the continuous development of the automotive industry, major auto manufacturers

The shape design of car lights is becoming more and more complicated, and the traditional processing method is difficult to be processed in a whole. As shown in Figure 2, if the CNC lamp is used for the production of the car light bead part, not only the processing cycle is long, but also the stitching seams produced by the splitting during the later stitching will also affect the surface treatment stage.

The use of rapid prototyping technology can eliminate this effect. The integral molding of the car light ring makes the surface treatment stage easier. Whether it is painting or aluminum plating, the effect is more ideal, and there will be no silting phenomenon.

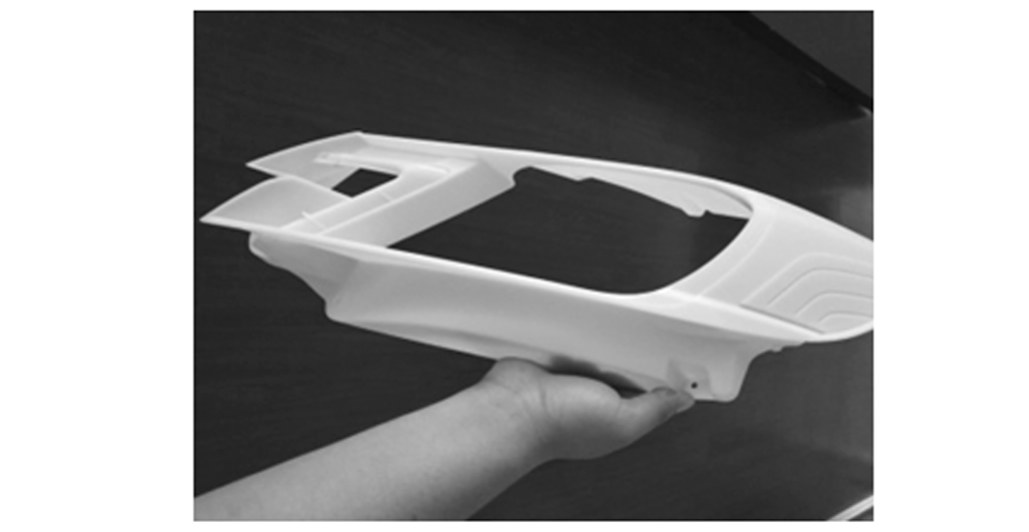

And after the decoration ring is installed in the car lamp, the assembly effect of the whole lamp is also more ideal. Similarly, if the lamp housing can be processed integrally,

The installation and positioning of the light source of the car lights are guaranteed with accuracy. In addition, the overall strength of the fast-formed lamp housing has been further improved. This allows preliminary reliability tests and light distribution tests to be carried out after the assembly of the entire lamp. So as to ensure that the degree of agreement between the sample of the lamp and the design reaches about 90%, or even higher.

Figure 4 shows the rapid prototyping lamp housing.

2. 3 Process comparison

Taking the production of a sample of the lamp housing as an example, from the processing accuracy and processing cycle

Table 1 shows the comparison between CNC machining and rapid prototyping in terms of time, cost and processing difficulty.

It can be seen from Table 1 that CNC machining is indeed higher in accuracy than rapid prototyping in the processing of sample parts of lamp housings, but rapid prototyping is superior to CNC machining in terms of processing cycle, cost, and processing difficulty. . And the rapid prototyping process makes the shell integrally formed, and the integrity and strength of the sample are better. In this way, the testability of the car light sample is also greatly improved. However, due to accuracy problems, rapid prototyping needs to be applied to other high-precision parts, further research and development are needed.

Fig. 4 Rapid prototyping housing

3 Silicone mold turning technology

3. 1 Production of silicone mold

Among many manufacturing processes, silicone molds account for their unique advantages

According to the manufacturing process, first of all, because the cost of silicone molds is extremely low, and the process is very simple, secondly, it can adapt to the current trend of short processing cycles, and at the same time has unique advantages in complex structural parts that machine tools cannot process. The steel mold will not have the influence of the draft angle. Under the influence of these conditions, the silicone mold has its own room for overturning.

The process flow for making a silicone mold sample is: RP prototype→frame manufacturing→silicone metering→vacuum defoaming→injecting silicone→hardening→knife cutting mold→removing the prototype→vacuum injection. Figure 5 shows the components of the silicone mold and Molding equipment

4 Conclusion

The above introduces the two current mainstream production processes through the rapid sample production of car lights, and explains the effects of the two processes on the manufacture of car lights, for the design and post-production of the car light manufacturing industry , Production provides an important basis for CNC processing and simple mold production, will continue to explore later.

December 24, 2019

February 27, 2020

June 05, 2020

March 09, 2020

November 14, 2019

December 18, 2019

Ningbo Expert Mould Plastic Co.,Ltd. can provide PVD process for your prototype products. MOQ 1 pcs / set. - Design advantages of PVD process: 1. Snowflake Design Effect 2. Multicolored Design Effect...

PVD(Physical Vapor Deposition) process coating Configuration of PVD factory: -Ten thousand class dust-free production workshop; -Automatic assembly line; -Fully automated robot coating system; -Check...

Injection mould factory in the process of development, sooner or later in a certain period of time will encounter the bottleneck of development, in the process of development will feel that the cost...

At present, China plastic mould manufacturers are constantly rising.From the beginning of the technical transformation investment, starting high, to now slowly to the scale, the direction of steady...

Email to this supplier

December 24, 2019

February 27, 2020

June 05, 2020

March 09, 2020

November 14, 2019

December 18, 2019

Send Inquiry

Ms. Lijuan Jiang

Tel:86-0574-87761816

Fax:86-0574-87761816

Mobile Phone:+86 13777106620

Email:project@ept-nb.com

Address:3# - No.506 Building Green Apple Business Square, Haishu District, Ningbo, Zhejiang

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.